Episode 46

The Industrial Revolution started with mechanical automation and is continuing today with electronic automation. This blog will explain the core elements of electronic automation, using parallels to the core elements of mechanical automation. Just like mechanical automation replaced human energy with fossil fuels, introduced a division of labour with specialized functions, and used capital equipment purchases to minimize or replace human labour, electronic automation decreases the need for human involvement.

Work does not happen without some form of energy. By using fossil fuels to enhance human energy the work output of a single individual was dramatically increased with mechanical automation. A single person with a shovel is no comparison to a hydraulically powered excavator. With electronic automation human labour is being replaced again. “Energy” inputs from human keystrokes and spreadsheets are being replaced with data warehouses, machine learning algorithms, and IOT infrastructure. Human “energy” inputs are being replaced by computation and instead of spending time performing data entry and administration, these tasks are being managed through automation.

Much like giving a human an excavator increases output over a shovel, commodity computer hardware is enabling a single individual to harness exponentially increasing levels of computation. This computation is being utilized to return insights from organizational data, perform classification tasks (on objects, text in images, speech, sentiment, etc.), optimize complex systems (financial portfolios, supply chains, weather forecasting, etc.), and much more. Mechanical automation created new jobs with, blacksmiths replaced by assembly line workers, and electronic automation is no different. As the need for administrators declines, we see new job roles and a significant increase in demand for highly specialized individuals that can perform tasks like architect and develop cloud solutions, engineer machine learning algorithms, develop business intelligence models, or create engaging social media content.

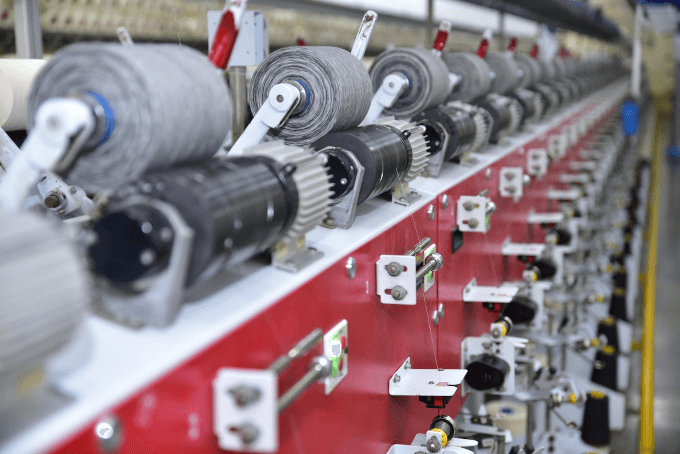

Lastly, the shift of generating value using capital purchases instead of additional labour continues with electronic automation. If we look at a modern organization, a single employee might be issued multiple devices, have numerous licenses for productivity software and SaaS solutions, and depending on the role be in control of expensive infrastructure. Each of these electronic tools reduces the amount of human labour required to accomplish a task. An example would be to use machine vision technology instead of human workers to spot defects in an assembly line output. In many cases, these technologies have been around for decades, but the components and software integrations are now dramatically less expensive, opening the opportunity for near ubiquitous deployment.

This was a high-level overview of the forces by which automation is rapidly changing industries. The next blog will explore software automation and offer some best practices for developing and maintaining software automation systems.

Last Updated: June 25, 2025