Episode 21

A digital twin is a digital replica of a living or non-living physical entity. In our last blog, we explored the concept of business intelligence where intuition is replaced with data driven decision making. The data that drives the decision has an underlying model based on a new layer of assumptions. The generation of model requires a new set of skills and experiences that are very different from traditional business decision making practices. There is little doubt that objectively gathered data is superior to opinions, so what happens when the model is sophisticated enough to capture the entire system? Digital twins represent the pinnacle of model development within a data driven decision making system.

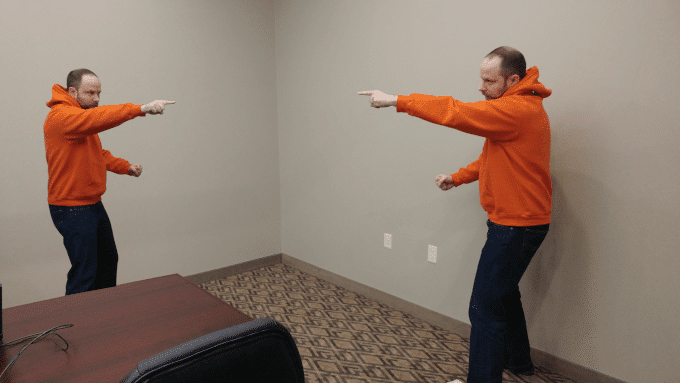

We live in two worlds: a world of atoms and a world of electrons. The world of atoms is the analog realm that can be best thought of as reality. It is the world of stuff. In the world of electrons, we create digital universes represented in strings of binary digits processed by computers. In the world of atoms if we want to perform an experiment we must gather and assemble materials and expend time to capture insights. In the realm of electrons, gathering and assembling resources is only limited by the ability to store and process information by the computers we use.

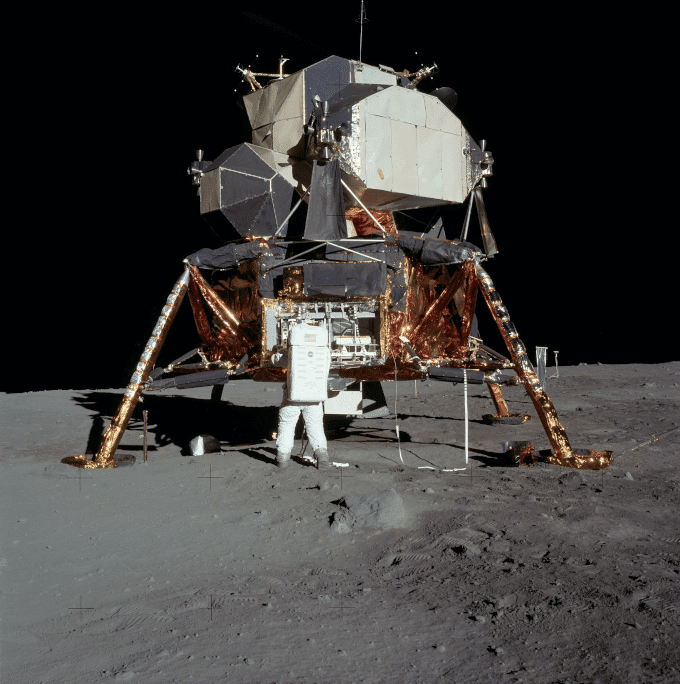

Materials and time are fixed constraints in the realm of atoms; and dynamic variables in the realm of electrons. Who wouldn’t want to copy and paste pizza if they could? The dramatic shift we see today is driven by the exponential decline in computation costs we have seen over the last 50 years in computation. The drop is so dramatic that any comparison to the physical world is nonsensical. If the realm of atoms experienced its own Moore’s law, all essential needs would be free, and the price of a cup of coffee in 1970 could cover the cost of a personal Apollo program today.

The scaling power of computation over the last half century is a challenging concept to comprehend. Digital twins are revolutionizing design practices and are helping to usher in the manufacturing 4.0 era. Traditionally business processes were locked into the physical constraints of the realm of atoms, and these business practices continue to persist to this day. Imagine if labour, material, transportation, or manufacturing requirements began falling exponentially. Business models would be shattered in short order.

There are two limiting factors to digital twins. The first, data informing the digital model must first originate in the physical world. Without observations of the realm of atoms, the realm of electrons has no connection back to reality. The second is that the accuracy of the simulation cannot perfectly represent the real world. Chaotic systems like weather and financial markets make long term predictions extremely challenging despite exponential improvements in computation.

Despite these limitations, the exponential decline in computation costs have enabled organizations to ask ever more complex questions of the digital models they create. Powerful software platforms enable business users to perform complex analysis on immense datasets, these workflows are no longer limited to the data professional. Computation is an exponential system, yet we operate in a far less dynamic reality of atoms, but organizations that can capture the exponential gains offered by digital systems can fast track their evolution away from their competitors.

Last Updated: June 25, 2025